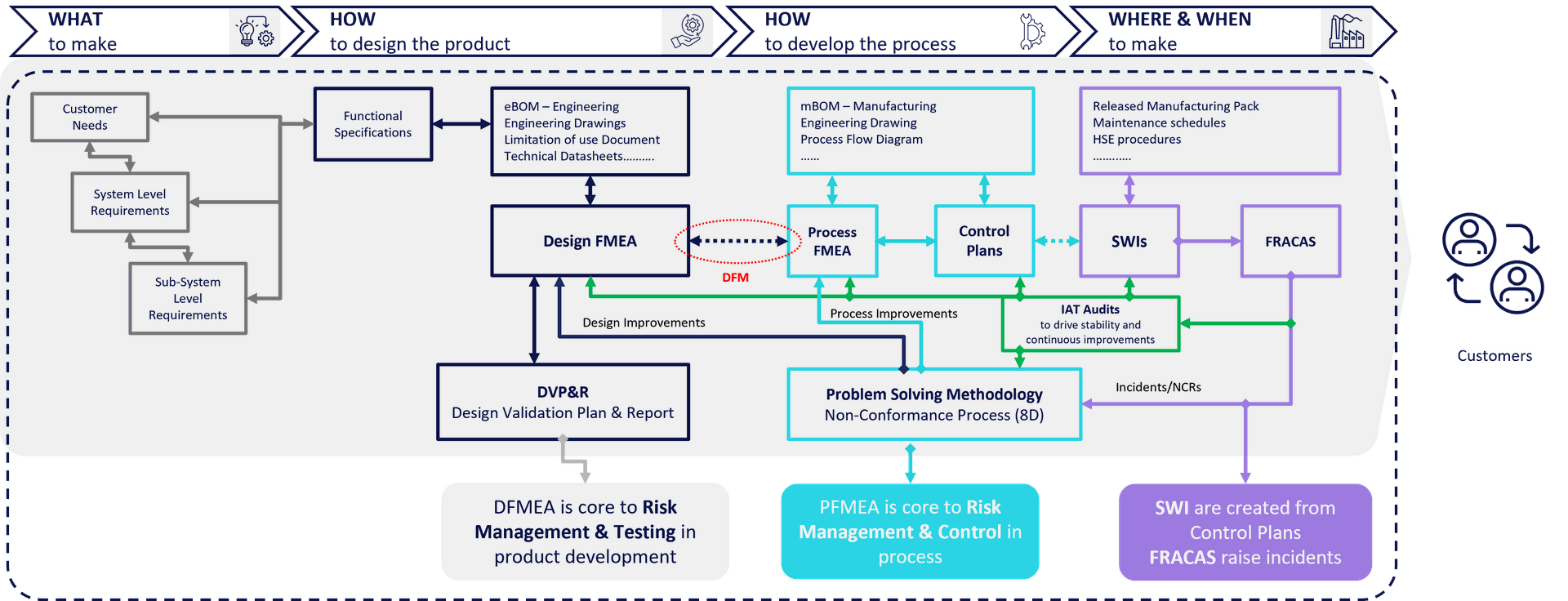

We have significant experience in the battery cell manufacturing domain, with product and process development and the importance of DFM.

Lets start discussing your FMEA needs today.

Contact us

What is DFM?

Design for Manufacture (DFM) is an engineering practice focused on designing products in a way that simplifies their manufacturing process. The goal of DFM is to optimize the product design to reduce production costs, improve quality, and enhance manufacturability, ultimately leading to faster production times and more efficient use of resources.

Simplicity: Designs should minimize complexity, reducing the number of parts and simplifying assembly.

Material Selection: Choosing materials that are readily available, easy to process, and compatible with manufacturing methods.

Standardization: Using standard components and materials to streamline production and reduce costs.

Tolerance and Fit: Designing parts with appropriate tolerances to ensure they fit together well during assembly without requiring excessive adjustments.

Process Consideration: Understanding the capabilities and limitations of the manufacturing processes being used (e.g., machining, injection moulding) and designing accordingly.

Assembly Efficiency: Considering how easily parts can be assembled, including orientation and accessibility during assembly.

What are the Benefits of DFM?

Cost Reduction: Lower production costs through streamlined processes and fewer materials.

Quality Improvement: Fewer defects and higher reliability due to simplified designs.

Faster Time to Market: Quicker production times lead to shorter development cycles.

Flexibility: Easier adaptation to changes in design or manufacturing processes.

plus many more ..

Failure Mode & Effect Analysis

Lets start solving your NPI challenges today

What are the requirements and challenges facing you in 2024 and beyond?