Semiconductor: 35% Efficiency Boost

How implementing manufacturing connectivity and real-time quality monitoring transformed operations and unlocked £1M of investment in the first year.

3x

CONFIDENCE INCREASE

90%

PRODUCT YIELD

£1M+

INVESTMENT UNLOCKED

100%

COLLABRATION

The Challenge - Complex Semiconductor Processing

The Client is a global leader in next-generation technology, faced a monumental challenge. Their strategic plan, "Project X" required scaling the production of a critical component from 1,000 to 100,000 units in under 12 months to meet aggressive engineering validation trial deadlines. The success of their entire product launch hinged on this scale-up.

However, their current manufacturing environment and systems are their achillies heal. It is built on a patchwork of disconnected systems, undocumented knowledge, and manual, error-prone processes. This ad-hoc model was simply not scalable and put the entire project, including the target of a 90% production yield, at immediate risk.

Our Approach

Project Scope

The project scope was simple, investigate the current Manufacturing Data Integration and produce a detailed Discovery Assessment of key findings, with clear plan of actions. The primary work packages (WPs) included the following areas:

Machine Data Integration

Machine Data Integration

Manufacturing Execution Systems

Manufacturing Execution Systems

Gap Analysis & Business Impact Findings

Gap Analysis & Business Impact Findings

Manufacturing Processes, Methods & Tools

Manufacturing Processes, Methods & Tools

The very first task is to create a clear picture which communicated a 1000 words, quickly effectively and with impact, to accelerate the pace of change. The plan is simple draw pictures and start piecing the puzzle together.

Deep Stakeholder Engagement: We conducted extensive workshops and interviews with stakeholders across the different functions of the business—from senior management and program leads to process engineers, production managers, IT, and facilities teams. This allowed us to understand the distinct pain points and requirements of each function.

Deep Stakeholder Engagement: We conducted extensive workshops and interviews with stakeholders across the different functions of the business—from senior management and program leads to process engineers, production managers, IT, and facilities teams. This allowed us to understand the distinct pain points and requirements of each function.

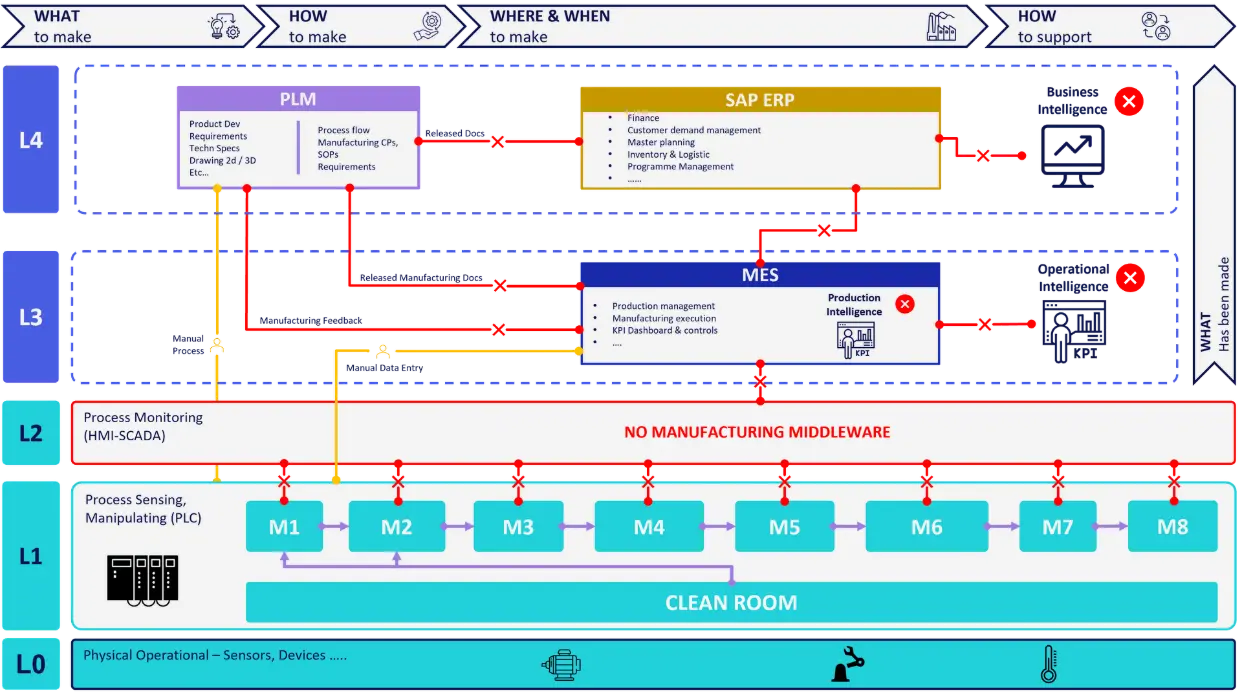

Comprehensive 'As-Is' Analysis: Mapped the existing systems, data flows, and processes. This created a clear, visual representation of the disconnected landscape (as seen in the "As-Is" Systems Overview), which became a powerful tool for aligning all stakeholders on the scale of the challenge, interfaces and dependencies of unconnected people, process and systems.

Comprehensive 'As-Is' Analysis: Mapped the existing systems, data flows, and processes. This created a clear, visual representation of the disconnected landscape (as seen in the "As-Is" Systems Overview), which became a powerful tool for aligning all stakeholders on the scale of the challenge, interfaces and dependencies of unconnected people, process and systems.

Technical & Process Deep Dives: The team analysed everything from existing and future machine connectivity capabilities to the IT/OT network architecture and facility infrastructure. Reviewed process documentation, control plans, and SOPs to perform a thorough gap analysis against industry best practices.

Technical & Process Deep Dives: The team analysed everything from existing and future machine connectivity capabilities to the IT/OT network architecture and facility infrastructure. Reviewed process documentation, control plans, and SOPs to perform a thorough gap analysis against industry best practices.

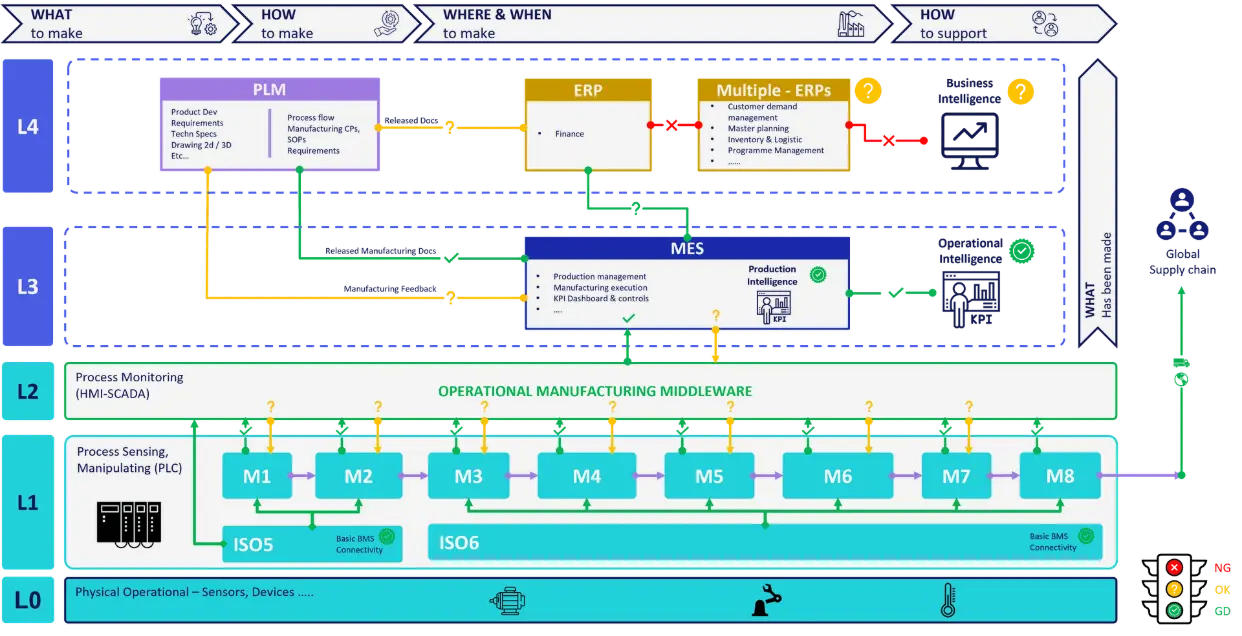

Building a 'To-Be' Vision: Working collaboratively with the SNAP team, we moved beyond simply identifying problems. We facilitated the creation of a shared vision for a future-state "To-Be" ecosystem—one that was integrated, data-driven, and scalable.

Building a 'To-Be' Vision: Working collaboratively with the SNAP team, we moved beyond simply identifying problems. We facilitated the creation of a shared vision for a future-state "To-Be" ecosystem—one that was integrated, data-driven, and scalable.

How We Delivered

We believe that true transformation comes from integrating people, processes, and technology, all underpinned by good data. We don't act as external consultants; we embed ourselves as trusted partners to gain a deep, holistic understanding of the business from both technical and operational viewpoints. Our approach is structured, methodical, and collaborative, focusing on adding real value;

Business Context - First step is to understand the business strategic direction, aims and ambitions. This can only come from direct discussions with senior business leaders, covering key areas like cost, quality, delivery timing, risk management

Business Context - First step is to understand the business strategic direction, aims and ambitions. This can only come from direct discussions with senior business leaders, covering key areas like cost, quality, delivery timing, risk management

People - For new systems to work, the people must use them. To get them there, we must see and help them make the transition. If they're confused, we explain the 'why.' If they're hesitant, we train them to build confidence. And if they feel ignored, we listen and involve them.

People - For new systems to work, the people must use them. To get them there, we must see and help them make the transition. If they're confused, we explain the 'why.' If they're hesitant, we train them to build confidence. And if they feel ignored, we listen and involve them.

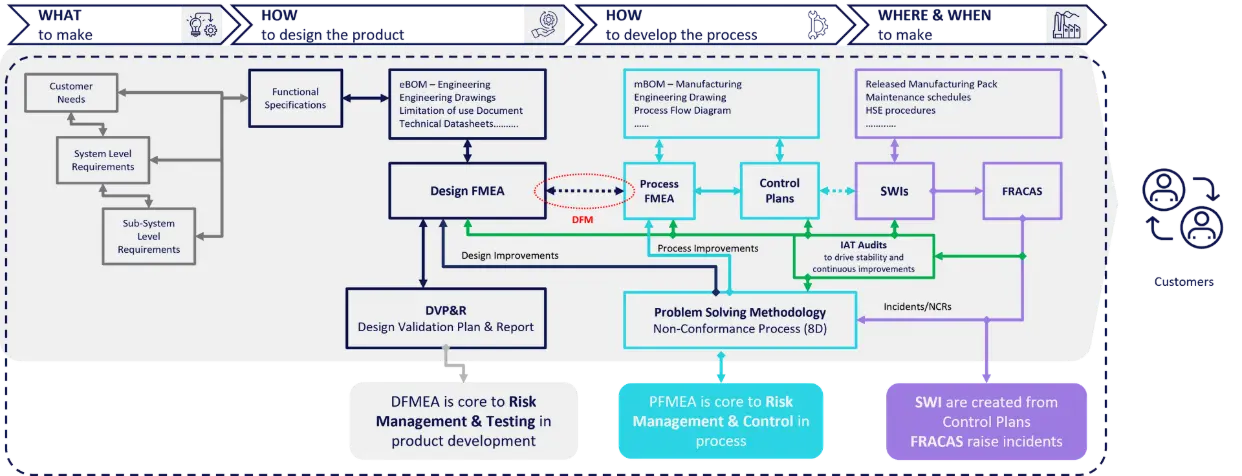

Product & Process - The below diagram outlines a simplified view of New Product Introduce (NPI) process and focuses on the processes, interfaces and the relationships from “What, How, Where and When” to make a product. The aim is to highlight the full lifecycle, how early-stage needs flow to product design, process development and into manufacturing operations, all of which needs to be managed effectively.

Product & Process - The below diagram outlines a simplified view of New Product Introduce (NPI) process and focuses on the processes, interfaces and the relationships from “What, How, Where and When” to make a product. The aim is to highlight the full lifecycle, how early-stage needs flow to product design, process development and into manufacturing operations, all of which needs to be managed effectively.

NPI Process Overview

Production & Facilities - Equipment reliability, availability, commissioning and performance commissioning, is essential to meet business goals. Currently all many of the machine are not connected to a central system for data collection. The aims is to enable communication and automatic data collection of all critical process and production parameters, necessary for report and analysis.

Production & Facilities - Equipment reliability, availability, commissioning and performance commissioning, is essential to meet business goals. Currently all many of the machine are not connected to a central system for data collection. The aims is to enable communication and automatic data collection of all critical process and production parameters, necessary for report and analysis.

"As-Is" Manufacturing Systems Landscape

"To-Be" Manufacturing Systems Landscape

IT & OT Infrastructure - Industry best practice requires segregating industrial machine networks from corporate IT to protect production from cybersecurity threats and ensure operational reliability. This is an area which requires attention to enable a scalable manufacturing operations.

IT & OT Infrastructure - Industry best practice requires segregating industrial machine networks from corporate IT to protect production from cybersecurity threats and ensure operational reliability. This is an area which requires attention to enable a scalable manufacturing operations.

Results & Impact

4 Weeks

ONE TIME DELIVERY

15

ENGAGEMENTS

£1M+

INVESTMENT UNLOCKED

100%

COLLABRATION

Key Achievements

A Blueprint for Scalable Success

A Blueprint for Scalable Success Established Machine Connectivity Pilot

Established Machine Connectivity Pilot Defined Enterprise Architecture

Defined Enterprise Architecture Eliminated Major Production Bottlenecks

Eliminated Major Production Bottlenecks

Key Findings & Summary

No Data Backbone: Critical information is fragmented across multiple systems (various PLMs, Google Docs). There is no single source of truth for product or process data, and no clear integration strategy for the new SAP ERP, making effective management and traceability very challenging.

Manual & Disconnected Operations: There is no automated data connectivity between machines and the clients MES. Production relies on manual, error-prone data entry, providing no real-time visibility into performance (OEE), quality, or process parameters.

Immature & Undocumented Processes: Core process knowledge has not been formally captured in a Process FMEA (PFMEA). This means manufacturing risks have not been systematically identified.

Fragmented Core Infrastructure: The facility's ability to maintain a stable cleanroom environment is unproven and a significant risk. Furthermore, there is no secure, dedicated network Operational Technology (OT) network for machine secure and reliable machine connectivity,

Global Eco System: There is a complex manufacturing supply chains of key "components", and 3rd Party contract manufacturers, which presents several risk and challenges to the scale up.

"TJ Digital Systems transformed our operations completely. The ROI was evident within 3 months, and we continue to see improvements every quarter."

Ready for Similar Results?

Let's discuss how we can transform your operations with proven methodologies.

LocationUK

LocationUK IndustryElectronics

IndustryElectronics