Operational excellence with IoT software

Data-driven EBIT improvement with smart operations. Isolated, high-maintenance solutions do not provide a competitive edge for your company. To succeed in a dynamic, volatile business world, you need a holistic process architecture that maximizes your digital capabilities and operational excellence.

Implement Your Digital Thread

Build a continuous, bidirectional flow of information across your entire product lifecycle. Start where you need to and expand at your own pace with our modular approach.

Eliminate Data Silos

Create an integrated ecosystem where software solutions exchange data in real time.

Single Source of Truth

Establish a reliable data foundation for processes and employees.

Bridge IT & OT

Connect ERP & CRM systems with shop-floor operations.

Closed Loop Engineering

Feed manufacturing insights back into product development.

Digital Production

Increasing efficiency in manufacturing through digitalization

-

Document Management

-

Asset Management

-

Maintenance Management

-

Operational Data Collection

Connectivity & Automation

Reduction of manual efforts and response times due to IoT connectivity

-

Machine Data Collection

-

Monitoring & Analytics

-

Process Automation

-

Preventive Maintenance

Smart Factory

Increasing effectiveness through cross-site standardisation and transparency

-

Closed Loop Engineering

-

Multi-site Production Control

-

Global Standardisation

-

KPI & Benchmarking

Choose Your Path

No matter which stage of digitalisation you are in, we support your pace and develop a future-proof strategy together. Choose the solution that best aligns with your goals.

My Shopfloor

Intuitive UI for machine operators – production plans, documents, and guided workflows at their fingertips.

Shopfloor Data Collection

Automated machine data collection with optional manual operator input for complete production visibility.

Real-Time KPI Dashboards

Extensive library of 100+ widgets for analysing production data – availability, productivity, quality.

Maintenance Management

Synchronise maintenance slots and production planning for optimised asset availability.

Multi-Site Standardisation

Centrally specify standardised processes, KPIs, and maintenance measures across all production sites.

Audit-Proof Documentation

Complete traceability of Q-status, shift conditions, downtimes, and shopfloor operations.

| Features |

Digital Production

Digitalise processes

|

Connectivity & Automation

Optimise & ensure quality

|

Production Network

Global coordination

|

|---|---|---|---|

| Document Management |

|

|

|

| Asset Management |

|

|

|

| Maintenance Management |

|

|

|

| Workforce Scheduling |

|

|

|

| Operating Data Collection |

|

|

|

| Tool Management |

|

|

|

| Machine Data Collection | — |

|

|

| Metrics & Analysis | — |

|

|

| Process Automation | — |

|

|

| Energy Management | — |

|

|

| Global Overview & Control | — | — |

|

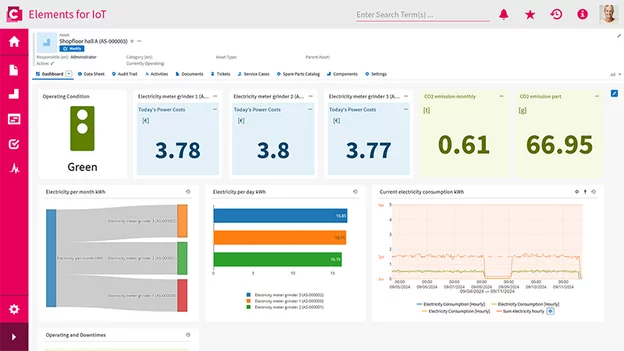

Automate value creation with data-driven processes

Elements for IoT enables you to automate, accelerate, and standardize business processes involving industrial assets. Operational data allows you to efficiently control value-adding activities, eliminating delays from manual intermediate steps or system breaks. This increases your competitiveness through improved responsiveness, increased throughput, and savings in indirect processes. Our software also provides a complete overview of your value streams, which supports in-depth analysis, benchmarks, and the standardization of methods and workflows. Your management benefits from meaningful KPIs and standardized reporting.

The era for experiments in Industry 4.0 is over. Isolated, high-maintenance solutions do not provide a competitive edge for your company. To succeed in a dynamic, volatile business world, you need a holistic process architecture that maximizes your digital capabilities and operational excellence.

With CONTACT Elements for IoT, you achieve EBIT-relevant effects through the end-to-end automation of business processes across the entire lifecycle of industrial assets. With the automation framework based on our modular Elements platform, you digitalize and scale your operations and establish digital twins of your assets. This allows you to create a data fabric that integrates machine and process data into knowledge contexts – for the analysis, control, and optimization of your business processes. At the same time, you pave the way for the use of analytics and AI applications.

Aftermarket Services Excellence and Satisfied Customers

Welcome to Elements for IoT - your Smart Services solution for efficient service processes. Experience a Customer Service Management software that helps your team effortlessly handle the increasing number of customer inquiries while boosting the efficiency of your service department. The result: satisfied customers and reduced internal costs. Deployed across 10+ global production sites, delivering measurable results for enterprise manufacturers.

Enhance Customer Experience

Deliver a first-class digital service experience with self-service portals, proactive communication, and seamless support.

Respond Faster

Reduce response times with IoT-connected field service and real-time visibility into product performance.

Predict Field Failures

Anticipate failures before they impact customers — moving from reactive to predictive service.

+1% per year

Productivity Increase Across all production sites30%

Downtime Reduction Through predictive maintenance10+

Global Sites Standardised processes worldwide

Quickly and effectively solve customer problems

With Elements for IoT, you can reliably plan, execute and document customer orders - anytime, anywhere, even via mobile devices. Your employees have access to all information about the service order - including documents and details about the service history and as-maintained status. Thanks to this transparency, you can solve customer problems faster and more efficiently.

FAQs

Get answers to common questions about our services, approach, and results

What is CONTACT Elements for IoT Smart Service?

With the Smart Service functions of Elements for IoT, you can digitalize service processes end-to-end and make them more efficient: from asset management with the digital twin to maintenance management. Your company establishes a central source of information that provides insight into customer organizations and makes planned maintenance measures transparent. You simplify the daily work of your service personnel (even on the go), reduce response times to customer inquiries, and generate new revenue streams through AI-based services like predictive maintenance.

Which companies benefit from the software

Elements for IoT's integrated service solution is industry-agnostic. It is suitable for all companies with high documentation and compliance requirements in service, and those looking to reduce costs through more efficient processes. A company's digital maturity level also doesn't matter: Our experts tailor the software to our customers' situation and develop a digitalization strategy that can be implemented step-by-step.

Is the software scalable?

Thanks to the modular architecture of Elements for IoT, you can gradually increase the digital maturity level of your customer service. Considering your current status, we collaboratively develop a digitalization strategy that you can implement at your own pace. Functions for the digitalization of production, energy management, or asset management can be added at any time.

Is it possible to integrate Elements for IoT into existing IT landscape?

Elements for IoT is based on our CONTACT Elements integration platform. It uses open standards such as HTML5, REST, or Python and enables the seamless synchronisation of third-party systems via powerful interfaces - whether from your own IT landscape or from suppliers. This allows you to easily connect your corporate IT (ERP, CRM, etc.) with Operational Technology (OT) and create end-to-end information flows from production to management level.