How can we enable you to make the right cell design decisions?

We support you in the material & component down selection process.

We have detail knowledge and knowhow in the electrical modelling and thermal simulation methodologies.

Offer insights to increased energy density and power density of the cell design.

Drive cost reduction activities to enable you scale faster and with less risk.

Guide you through key challenges as you prototype and develop your process.

Lets start discussing your cell design needs today.

Contact us

Cell Development

Battery cell development and industrialisation is inherently difficult to get right;

Challenge to establish clear cell design requirement and performance targets.

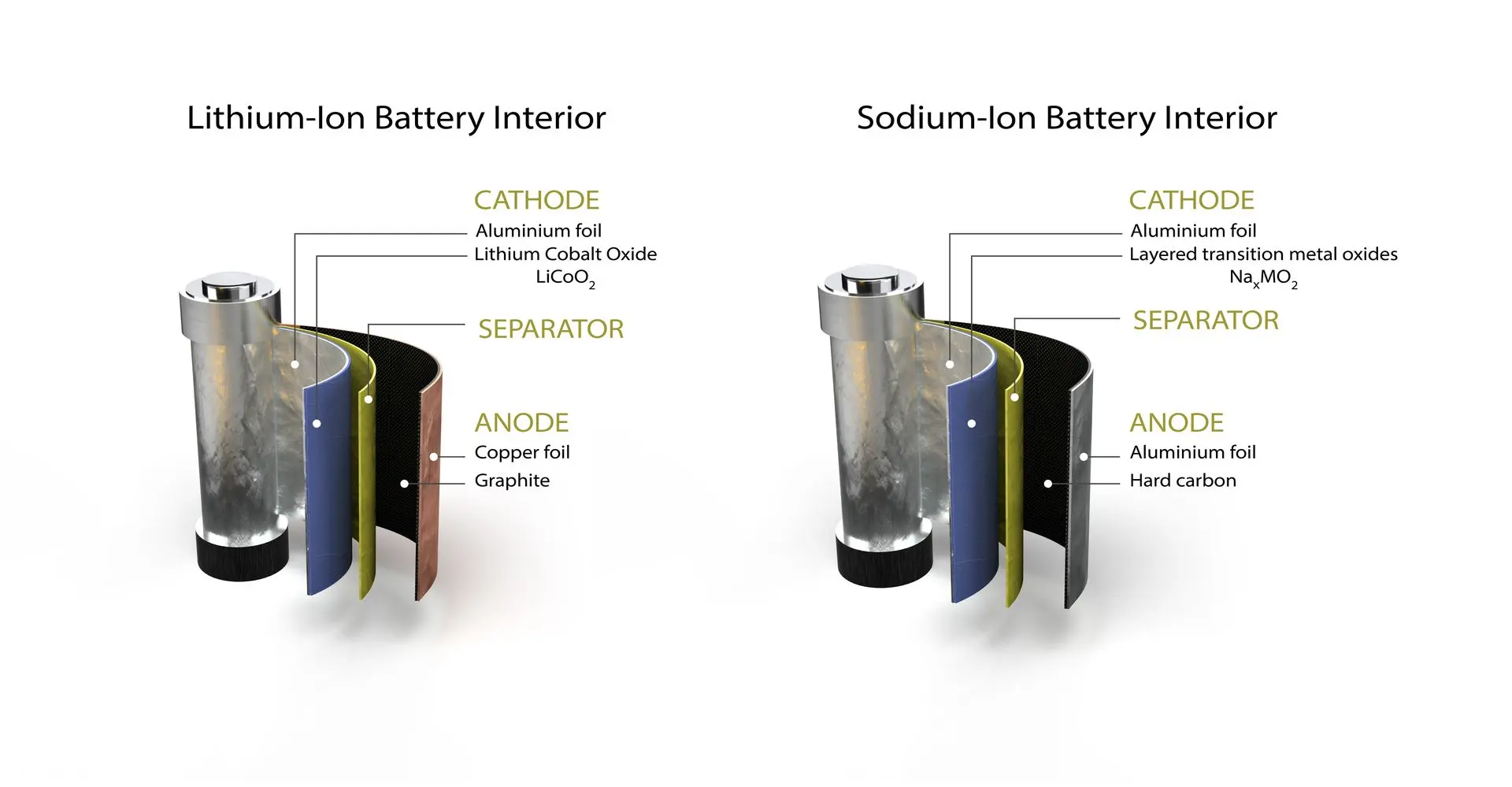

How do you down select the right materials and cell form factor for your application.

Multi-domain experience needed to develop cells; Electro-Chemistry, Mechanical, Electrical and Simulation Engineering.

How do you manging design and process changes as you scale from lab -> pilot -> industrialisation -> volume manufacture.

How do you manage the technology development to deliver the right product to the customer.

Key thoughts and consideration in your cell development

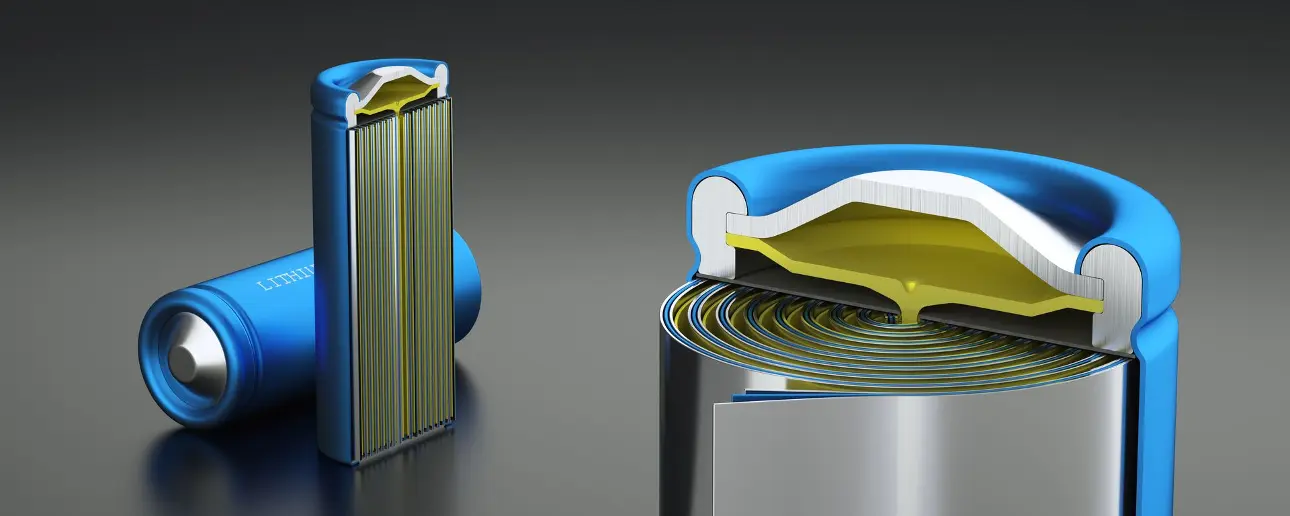

Application and manufacturing demands are driving cell format evolution, materials selection as the need for cost reduction increases.

Choosing the right cell format for the target application really matters, many different pros and cons between cylindrical, pouch and prismatic cells.

Develop and innovate or get left behind in the race.

Make sure you consider the full cell life cycle in your design requirements; performance, manufacturing, circularity & recycling

Battery Cell DFMEA

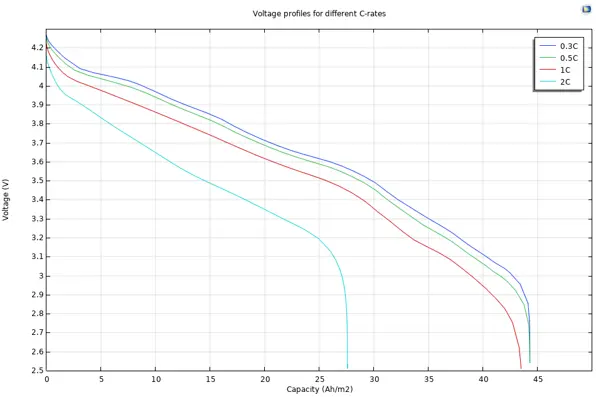

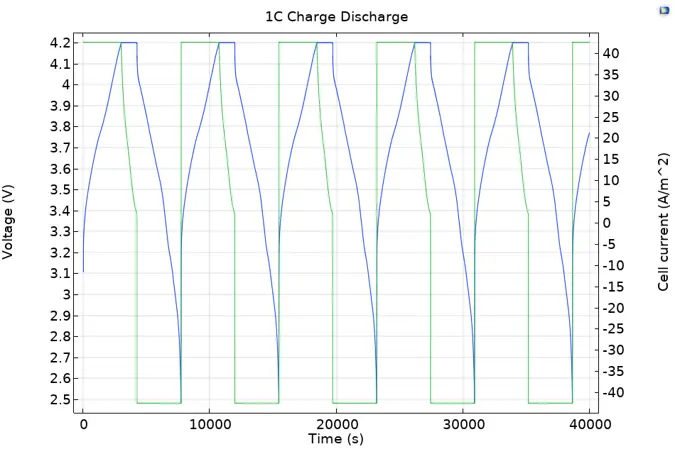

Cell Rate Capability & Cycling

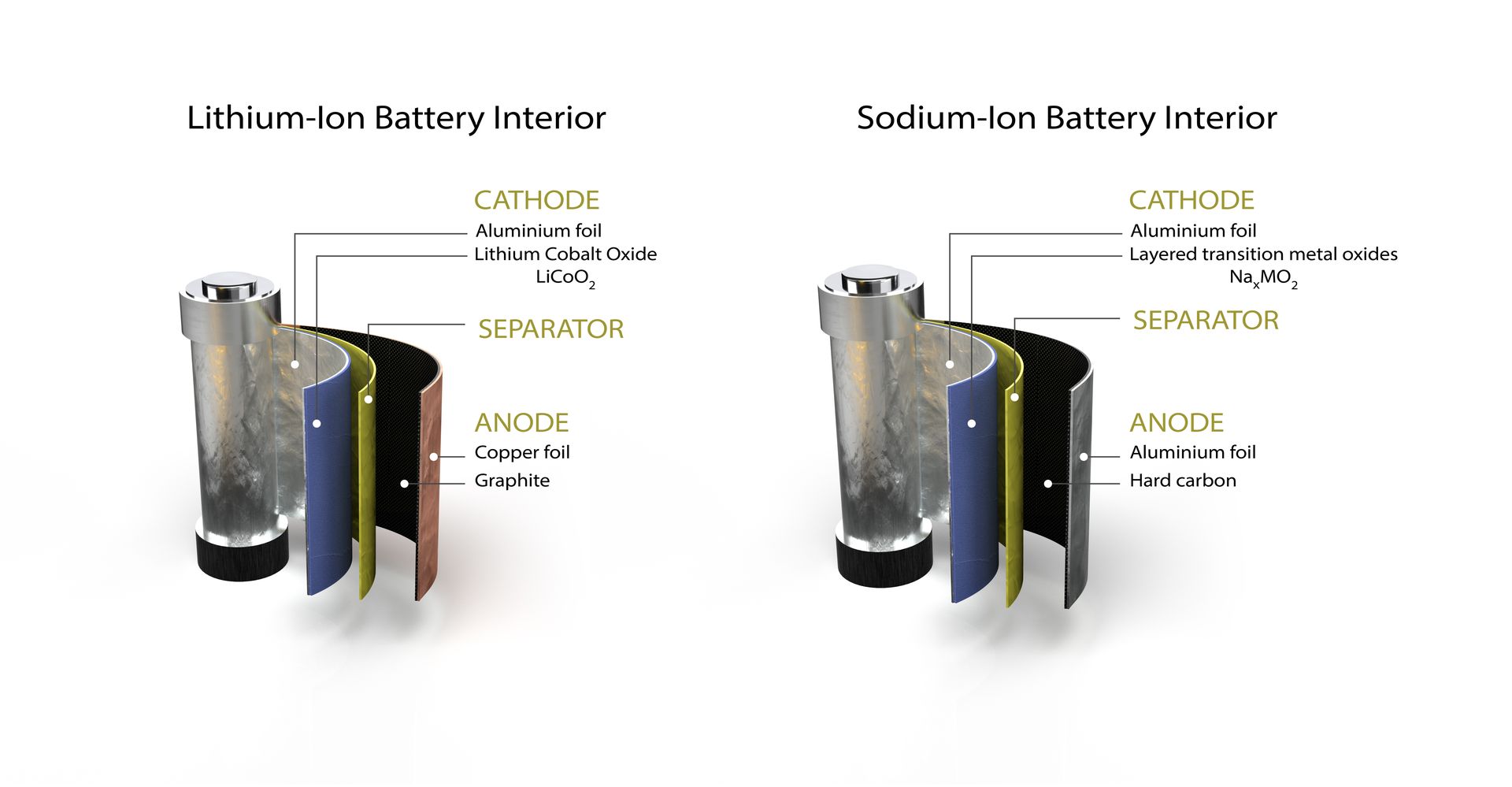

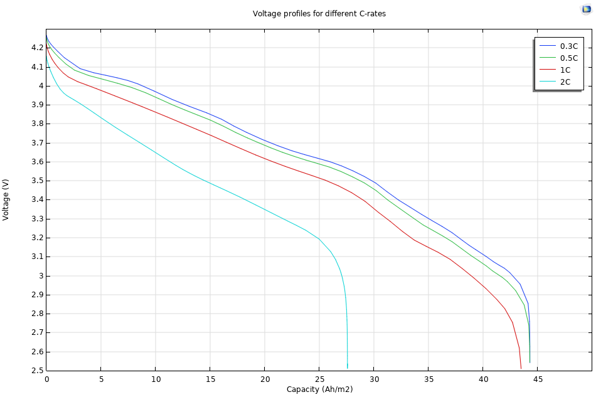

One of the first steps in the design process is to model expected C-rate capability, Charge/ Discharge Cycling

As you increase your c-rate demand on your cell the capacity can significantly reduce.

Understanding the voltage profile of your cell design in charge and discharge is vital to establishing the performance characteristics.

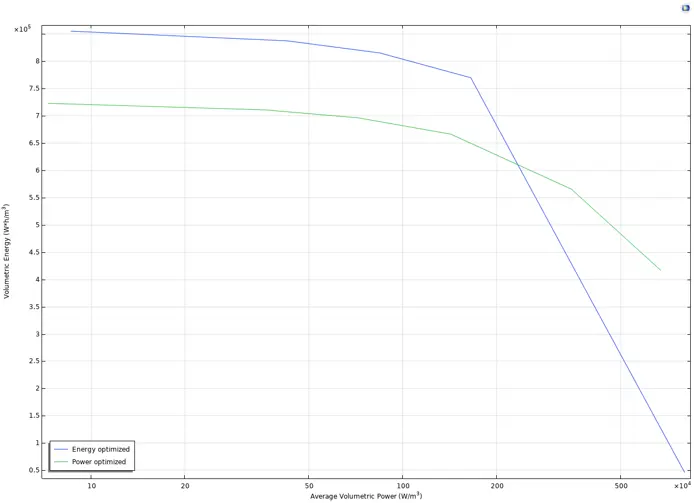

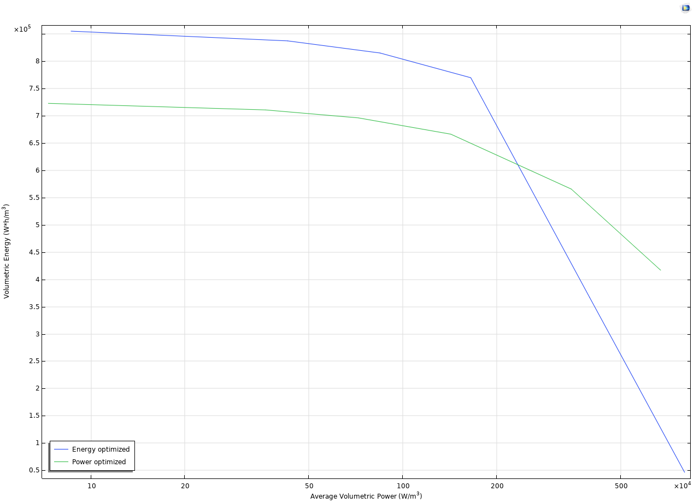

Energy vs Power Density Optimisation

Having clear understanding of the target applications demand / drive cycle will significantly aid the cell optimisation process. The graph below show how you can optimise for volumetric energy density or volumetric power density.

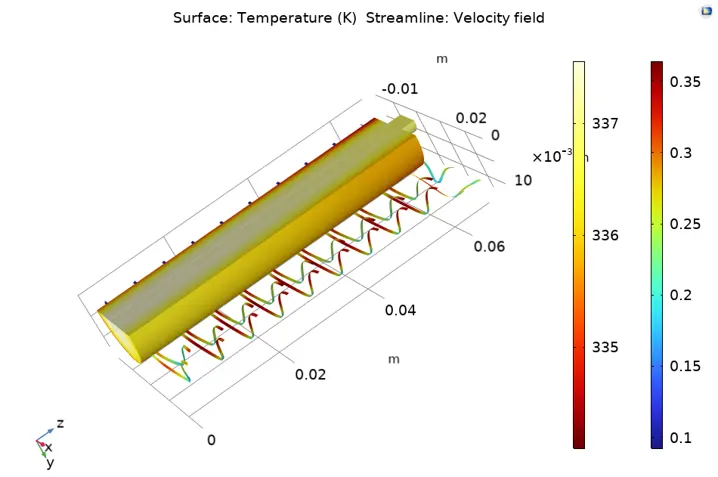

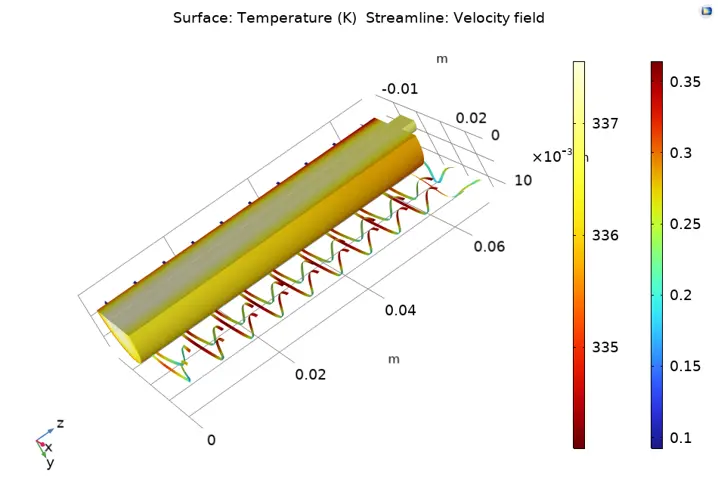

Cell Thermal Simulation

A fundamental component of the cell design process is understanding how the cell behaves under different demand and environmental conditions, the thermal response significantly affects the performance, cycle life, mechanical design and component selection of the cell.

Lets start solving your cell development challenges today

What are the requirements and challenges facing you in 2024 and beyond?