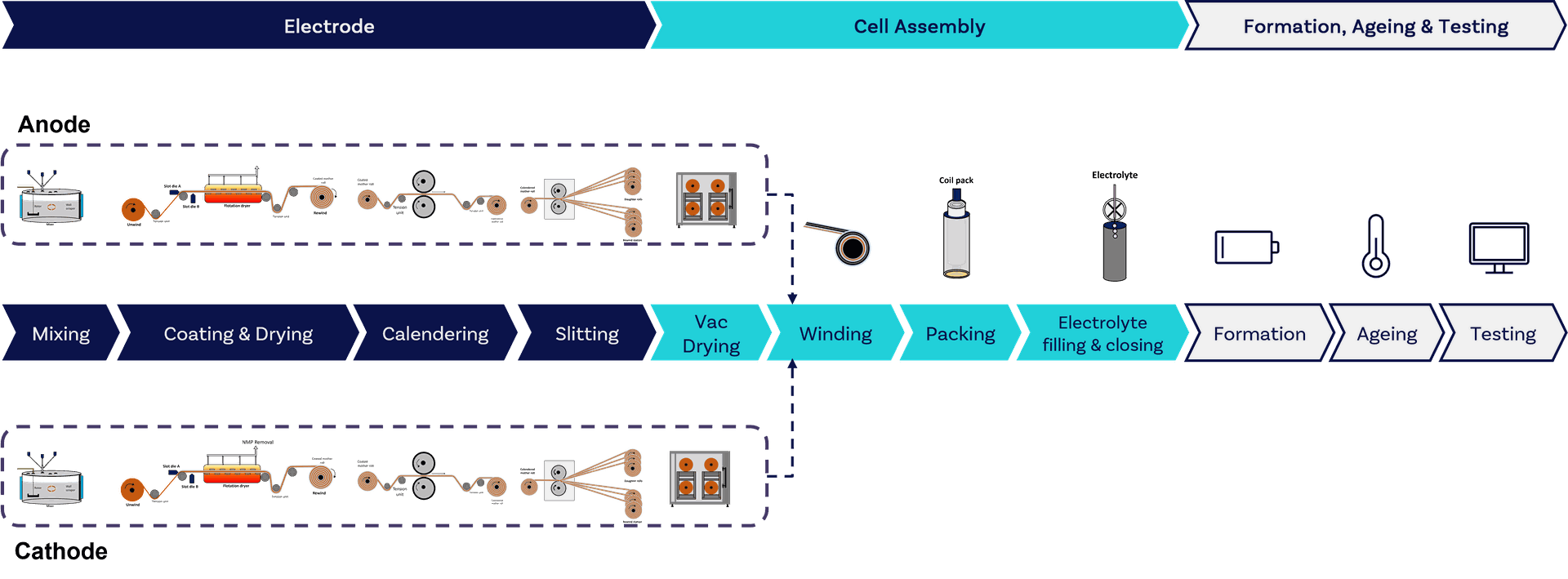

There are 3 main processes in battery cell production;

Electrode,

Cell Assembly

Formation, Ageing & Testing

We provide expertise on the process scale up methodologies and best practices to reduce your risk.

Lets start discussing your process needs today.

Contact us

What are the Battery Cell Manufacture Challenges?

Supply Chain: Volume manufacturing relies on a consistent supply of materials. Disruptions due to geopolitical issues, natural disasters, or logistical challenges can significantly affect production schedules.

Material Handling: The raw materials used in battery cells, such as cathode and anode materials, are often sensitive to moisture and air. Proper handling and storage are critical to maintain material integrity and prevent contamination.

Precision and Quality Control: The manufacturing process requires high precision in materials and assembly. Even minor deviations can lead to performance issues or safety hazards, necessitating stringent quality control measures.

Cost Management: The cost of raw materials, labour, and technology can fluctuate significantly, impacting overall production costs. Manufacturers must balance these costs while maintaining competitive pricing.

Scalability: Rapidly increasing demand for lithium-ion batteries, particularly in electric vehicles and energy storage systems, requires manufacturers to scale up production efficiently. This can be challenging, especially for new entrants or smaller manufacturers.

Technological Advancements: The battery technology landscape is constantly evolving, with new chemistries and designs emerging. Staying ahead of these advancements requires ongoing investment in research and development.

Safety and Thermal Management: Lithium-ion batteries can pose safety risks, including thermal runaway and fire hazards. Manufacturers must implement robust safety measures and effective thermal management systems to mitigate these risks.

Environmental Compliance: Manufacturing processes must adhere to environmental regulations, which can vary by region. This includes managing waste, emissions, and resource usage, adding complexity to operations.

Skills & Training: Skilled labor is essential for high-quality manufacturing. However, there may be a shortage of trained personnel, necessitating investment in workforce development and training programs.

Automation and Technology Integration: Implementing advanced manufacturing technologies, such as automation and AI, can enhance efficiency but requires significant upfront investment and integration efforts.

Battery Cell Manufacturing Infographic

Lets start solving your process challenges today

What are the requirements and challenges facing you in 2024 and beyond?