FRACAS is a key component to any Quality Management System, we offer the following;

Setup of FRACAS process, tools & methodologies, using Relyence software tools.

FRACAS workshops & training sessions.

We offer flexibility and deliver the results you need, so lets start discussing your FRACAS needs today.

Contact us

What is FRACAS?

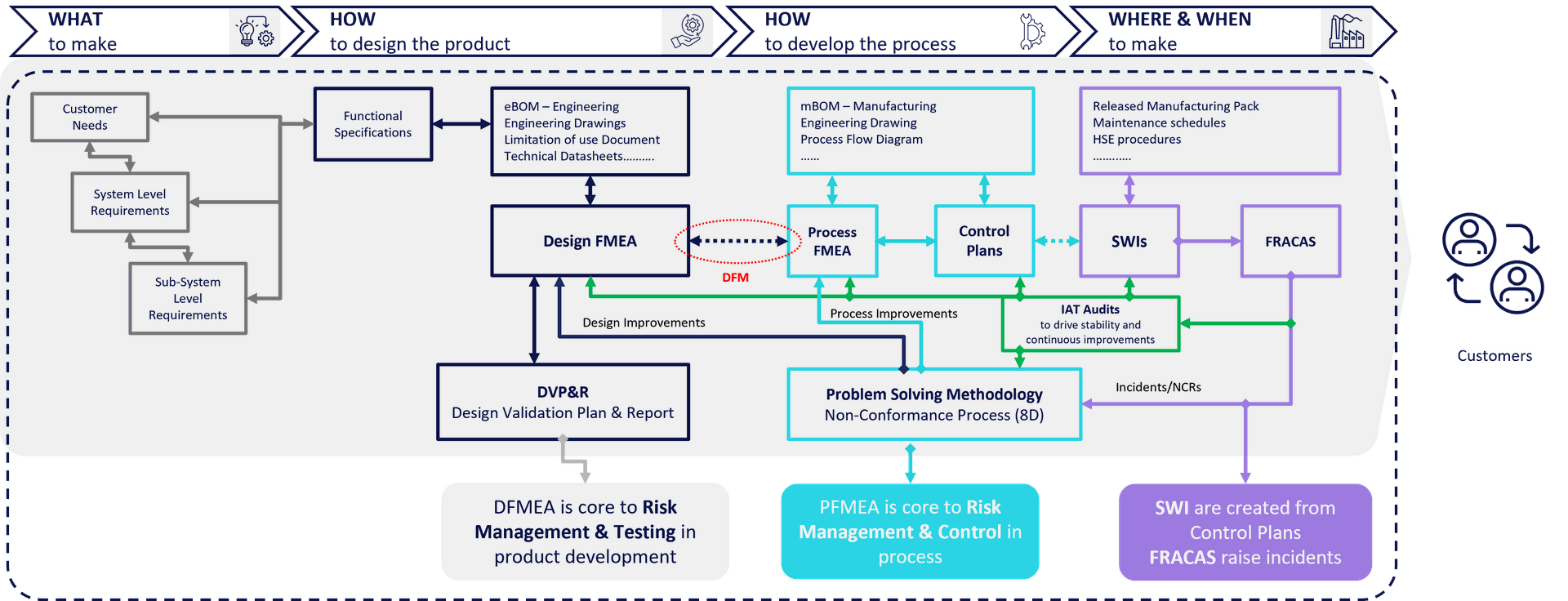

Failure Reporting and Corrective Action (FRACAS) provides a complete tracking and control framework for handling issue management process.

FRACAS is a systematic process used by to identify, report, analyse, and rectify failures in products, processes, or systems. This approach is critical for enhancing reliability, safety, and overall quality

FRACAS involves documenting instances of failure or nonconformance in products, systems, or processes. This documentation serves as the foundation for analysis and corrective action, with to goal to prevent recurrence and improve processes. It improves standardisation of documentation; forms or databases to ensure consistency and completeness in reporting

FRACAS drives structure and clear definition of failures, including specifics such as the time, location, and context in which it occurred.

FRACAS ensures that reports are communicated to relevant stakeholders, including management, engineering, and quality assurance teams. It also can encourage a culture of transparency and accountability amongst cross-functional teams.

FRACAS is closely linked with root cause analysis to identify the underlying cause(s) of the failure using methodologies such as Fishbone diagrams, 5 Whys, or FMEA

FRACAS provides action planning and prioritisation to address the identified root causes, which may involve changes in design, processes, training, or materials. It also ensures that resources are allocated and responsibilities assigned.

When to use FRACAS?

New Systems or Redesigns: During the design and testing of new products / systems or existing products / systems undergoing significant changes. FRACAS helps identity and address failure, before they reach the market.

Post-Implementation Reviews: When failures or incidents occur, FRACAS is essential for investigating the incident, documenting it, and implementing corrective actions

Quality Control & Assurance: FRACAS is used to monitor and analyse defects found during quality inspections or testing phases, facilitating timely corrective actions.

Industry Regulations: In regulated industries (e.g. aerospace, healthcare), to ensure compliance with safety, quality and regulatory standards.

Maintenance and Reliability Engineering : When equipment or systems fail, FRACAS helps determine root causes and implement maintenance strategies to prevent future issues.

What are the Benefits of FRACAS?

Improved Reliability: By systematically identifying and analysing failures, organizations can enhance the reliability of their products or systems.

Cost Reduction: By addressing root causes of failures, and implementing corrective actions businesses can reduce costs associated with warranty claims, rework, and downtime.

Enhanced Safety Culture: In safety-critical environments, effective FRACAS implementation can help identify potential hazards early, reducing the risk of accidents.

Improved Documentation: FRACAS promotes thorough documentation of failures and corrective actions, aiding compliance with industry standards and regulations.

Stakeholder Confidence: Demonstrating a robust FRACAS can enhance stakeholder confidence in an organisation’s commitment to quality and safety.

Customer Satisfaction: By improving product reliability and safety, FRACAS contributes to higher customer satisfaction.

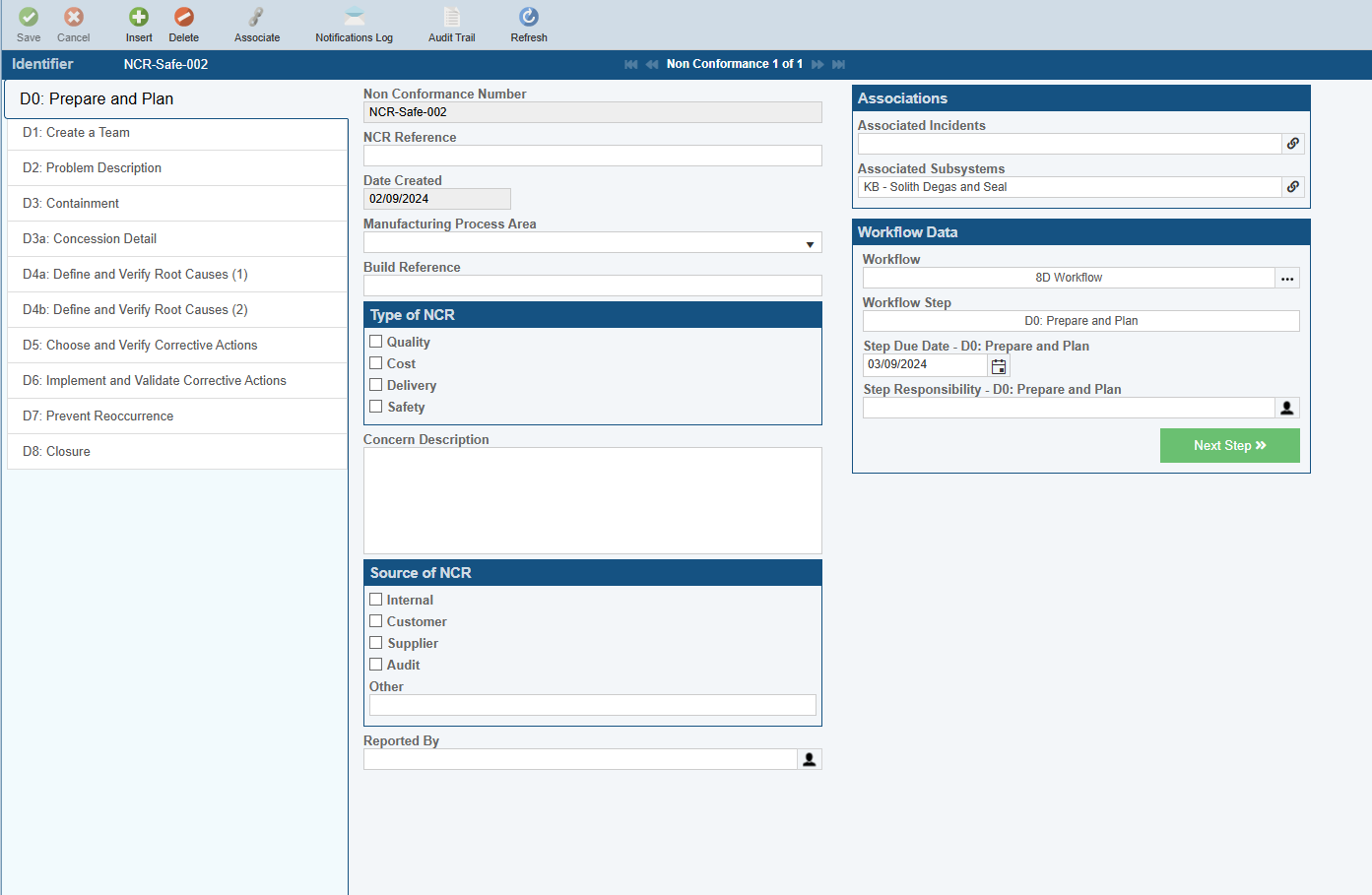

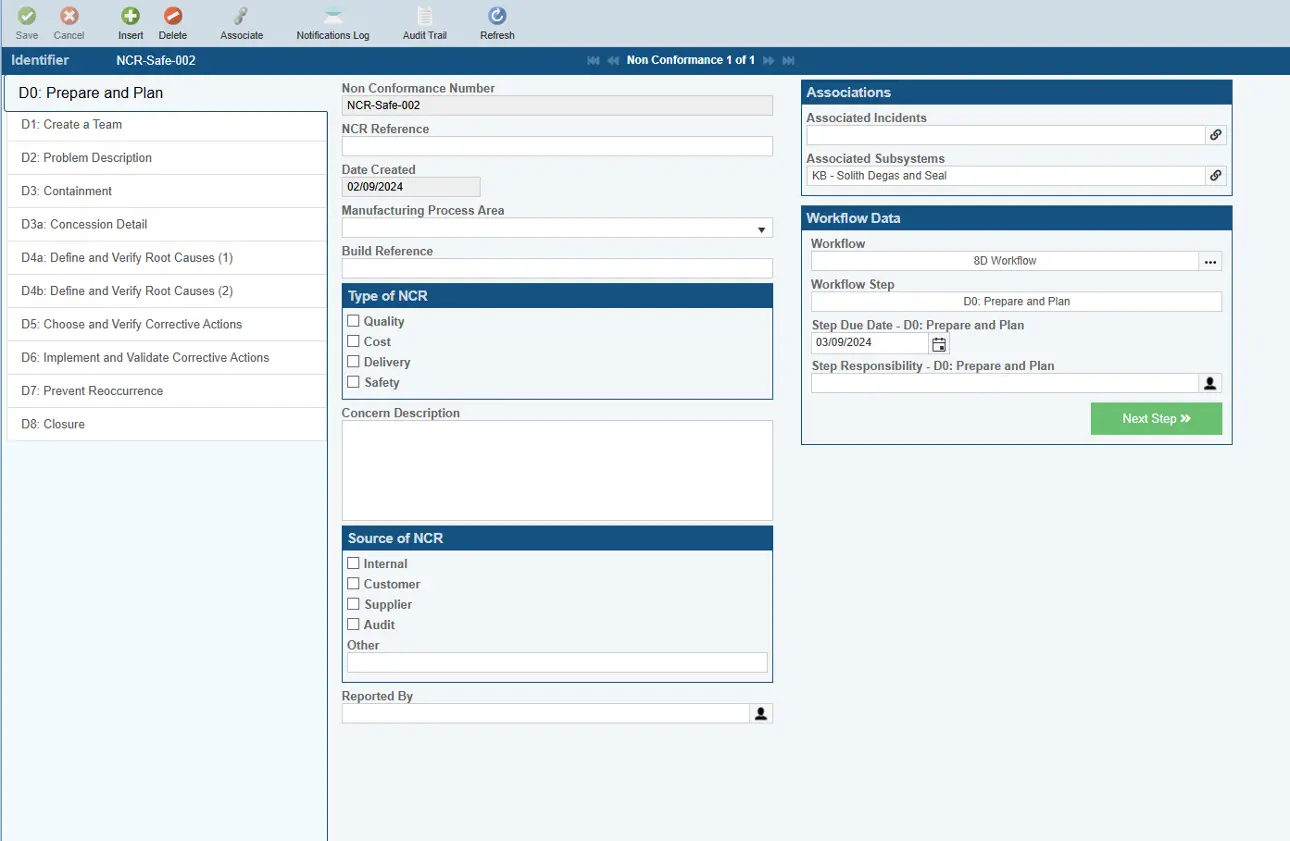

8D Example

Lets start solving your FRACAS challenges today

What are the requirements and challenges facing you in 2024 and beyond?