Definition

A Digital Ecosystem is a network of interconnected digital technologies, platforms, applications, and services that work together to create value for users and stakeholders. A Digital Twin is a:

'A Digital Twin is a dynamic virtual representation of physical assets, processes, or systems'

Or a more comprehensive version of the definition:

“A digital twin is a dynamic, real-world virtual representation of monitorable, connected (or soon-to-be connected), unique physical assets, processes, or systems. Representing past, present, and future data, digital twins deliver smart solutions by integrating cross-domain services, using smart software (like machine learning, simulation, VR/ AR) to help you understand and interact with the physical world and shape the future with the objective of improving performance and/or reducing risks.’’

ISA 95 Framework & Layers

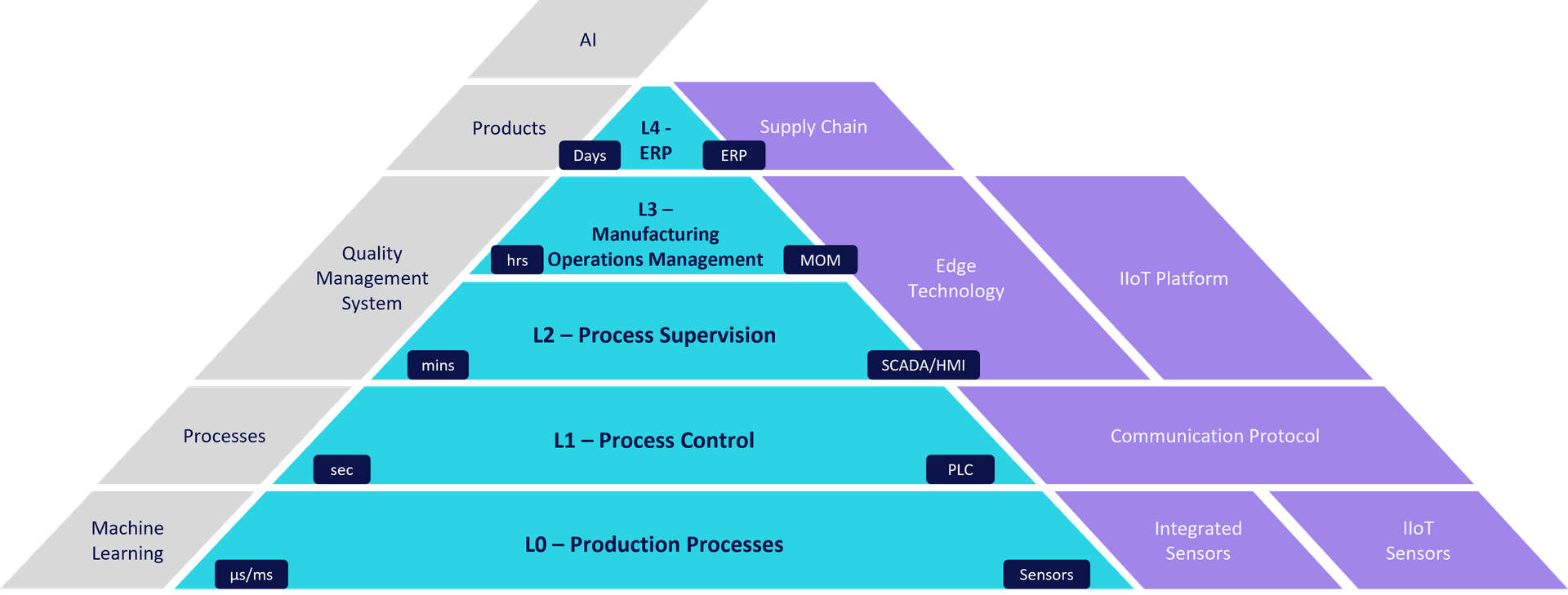

ISA-95 is an international standard for integrating enterprise and control systems, organised into layers that span physical processes to business-related activities. It provides a framework facilitating efficient communication and coordination between diverse elements of manufacturing operations.

Its official name is “ANSI/ISA-95 Enterprise-Control System Integration” (known internationally as IEC/ISO 62264). Leveraging this standard can bring a company-wide perspective to system integration that allows you to take thousands of actions and data points and boil them down in an understandable framework. It focuses on activities - and it is meant to define and integrate the activities between business and manufacturing systems like, Enterprise Resource Planning (ERP) on one hand and Manufacturing Execution Systems (MES) and Manufacturing Operations Management (MOM) on the other. The standard even covers the detailed level of sensors and the physical processes.

These models can be used to determine which information has to be exchanged between systems for sales, finance, and logistics, and systems for production, maintenance, and quality. This information is structured in UML models, which are the basis for the development of standard interfaces between ERP and MES systems. The ISA-95 standard can be used for several purposes, for example as a guide for the definition of user requirements, for the selection of MES suppliers, or as a basis for the development of MES systems and databases.

ISA-95 incorporates the layers model of technology and business processes for manufacturing enterprises as levels for the standard. These levels are:

Level 4 - Defines the business-related activities needed to manage a manufacturing operation.

Level 3 - Defines the activities of workflow to produce the desired end products.

Level 2 - Defines the activities of monitoring and controlling the physical processes.

Level 1 - Defines the activities involved in sensing and manipulating the physical processes.

Level 0 - Defines the actual physical processes.

See Infographic below for more detail on what systems and devices sit where in the ISA95 hierarchy and associated external systems.

TJ Digital System 2024

Underlying Concepts

Properly defining some of the key underlying concepts will reduce the amount of confusion when discussing digital twins.

A lot of technology is labelled as a digital twin nowadays. And even when actual digital twins are pointed out, they come in many guises, because different areas of society have varying digital twin requirements and expectations. We can however distinguish a number of common concepts that we can use as defining characteristics of digital twins.

First and foremost, digital twins mirror the current or future physical world and therefore should at the very least consist of physical assets (objects or people) with interactions in processes that are both modelled.

Assets should be identifiable through a unique ID, or we would be at a loss on how to monitor interactions in processes or how to model the expected outcomes of those processes.

Monitoring can be performed in real-time (instant, e.g. streaming data), near real-time (slight delay, e.g. transaction monitoring) or even in batch (longer delays), depending on the use case.

The system should support data exchanges between digital twins, so larger systems can be built from smaller modules. If any of these concepts are missing in a software system, we should not label it a digital twin.