When FTA and FMEA are coupled together they become a very powerful and effective methodology for your business. We have a detailed knowledge of the FTA process to ensure good failure analysis coverage, using the Relyence FTA software tool. We offer the following;

Setup of FTA process, tools & methodologies.

FTA facilitator support and training.

Completed FTA from start to finish, including linkages to FMEA.

Lets start discussing your FTA needs today.

Contact us

What is FTA?

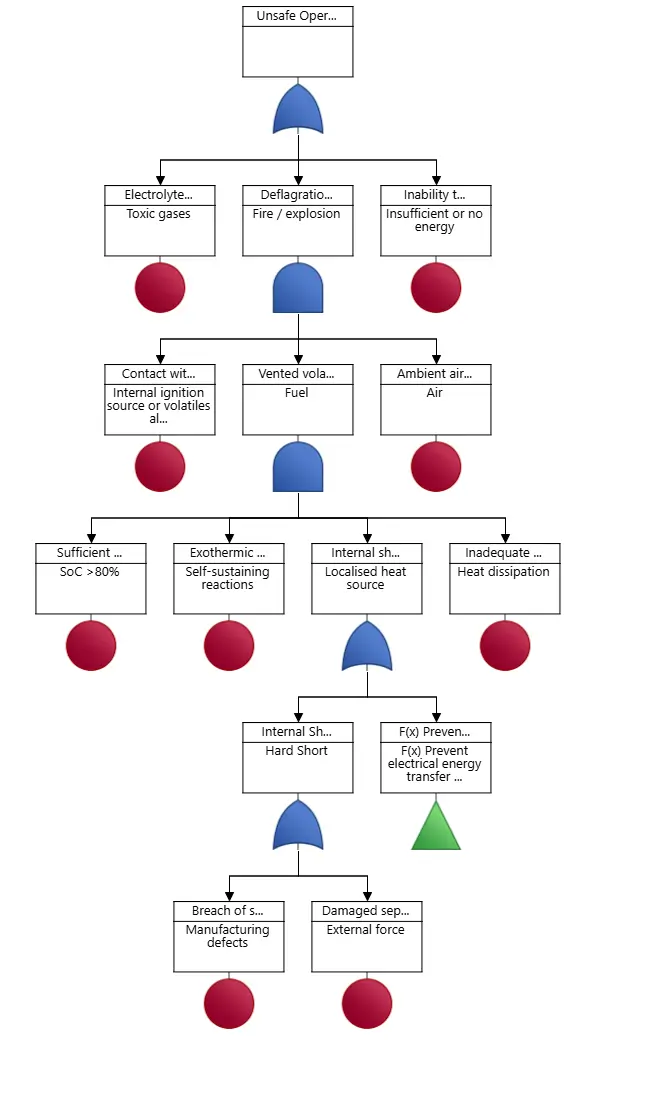

Fault Tree Analysis (FTA) is used in reliability engineering and risk analysis to identify and analyse undesired states of a system, using Boolean logic. FTA is a graphical representation of a collection of events and conditions that lead to an undesired event or system failure.

It is is a deductive, top-down approach and is a powerful methodology that assesses the various causes and consequences that can lead to system failure.

FTA helps identify potential failure paths before they occur, using collaboration and a cross-functional team of experts, allowing organisations to implement preventive measures. This proactive approach reduces the likelihood of failures and enhances safety.

By tracing back from an undesired event, FTA facilitates the identification of root causes. These root causes can be cross referenced with an FMEA process to ensure all possible causes have been identified and mitigation actions assigned.

When to use FTA?

High-Risk Industries: FTA is essential in industries such as aerospace, nuclear, and chemical processing, where safety is paramount. It helps identify potential hazards and failure modes that could lead to catastrophic events.

New Systems or Redesigns: During the design and development of new products / systems or existing products / systems undergoing significant changes. FTA helps identify potential failure modes early, allowing for design modifications to enhance reliability or how modifications might introduce new failure modes.

Post-Incident Investigations: When failures or incidents occur, FTA can help determine the underlying causes, facilitating effective corrective actions.

Process Improvement: FTA can be used to analyse production processes, identifying potential failure points that could lead to defects and ensuring higher quality standards.

Team Training: FTA can be used as a training tool to educate teams about system interactions and failure modes, fostering a culture of safety and awareness.

Preventive Maintenance: FTA can identify critical components that are likely to fail, allowing for targeted maintenance strategies to reduce downtime.

Risk Prioritization: When assessing risks in a project or system, FTA helps prioritize failure modes based on their likelihood and potential impact, guiding resource allocation for mitigation efforts.

Battery Cell Example

Lets start solving your process challenges today

What are the requirements and challenges facing you in 2024 and beyond?